Testing and flushing hoses for marine equipment

Pedroncelli Srl offers its customers a testing and flushing service for assembled flexible hoses for hydraulic systems.

This service is offered both for hoses joined internally and for assemblies made by others in the industry.

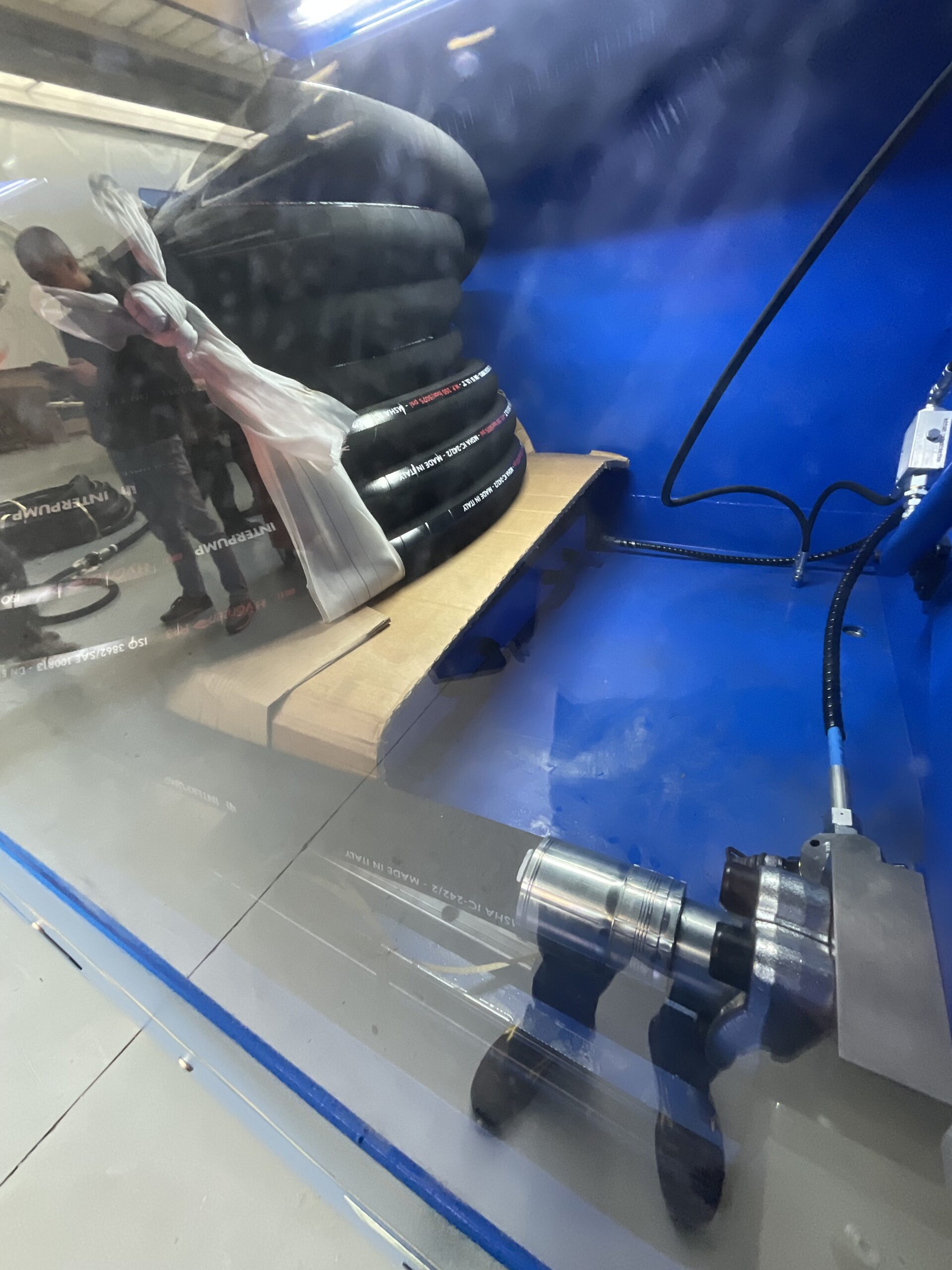

The company has a test bench and a fluxing station that allow it to work on hoses of different diameters and without length or connection constraints.

The operations are carried out in the presence of an inspector and in accordance with the characteristics required by the relevant certification body and the customer.

The testing and flushing of 2″ R15 and R2AT pipes with a variable length range of up to 52 m per pipe is a recent development.

Below is a detailed description of the testing and fluxing phases performed.

Hose testing

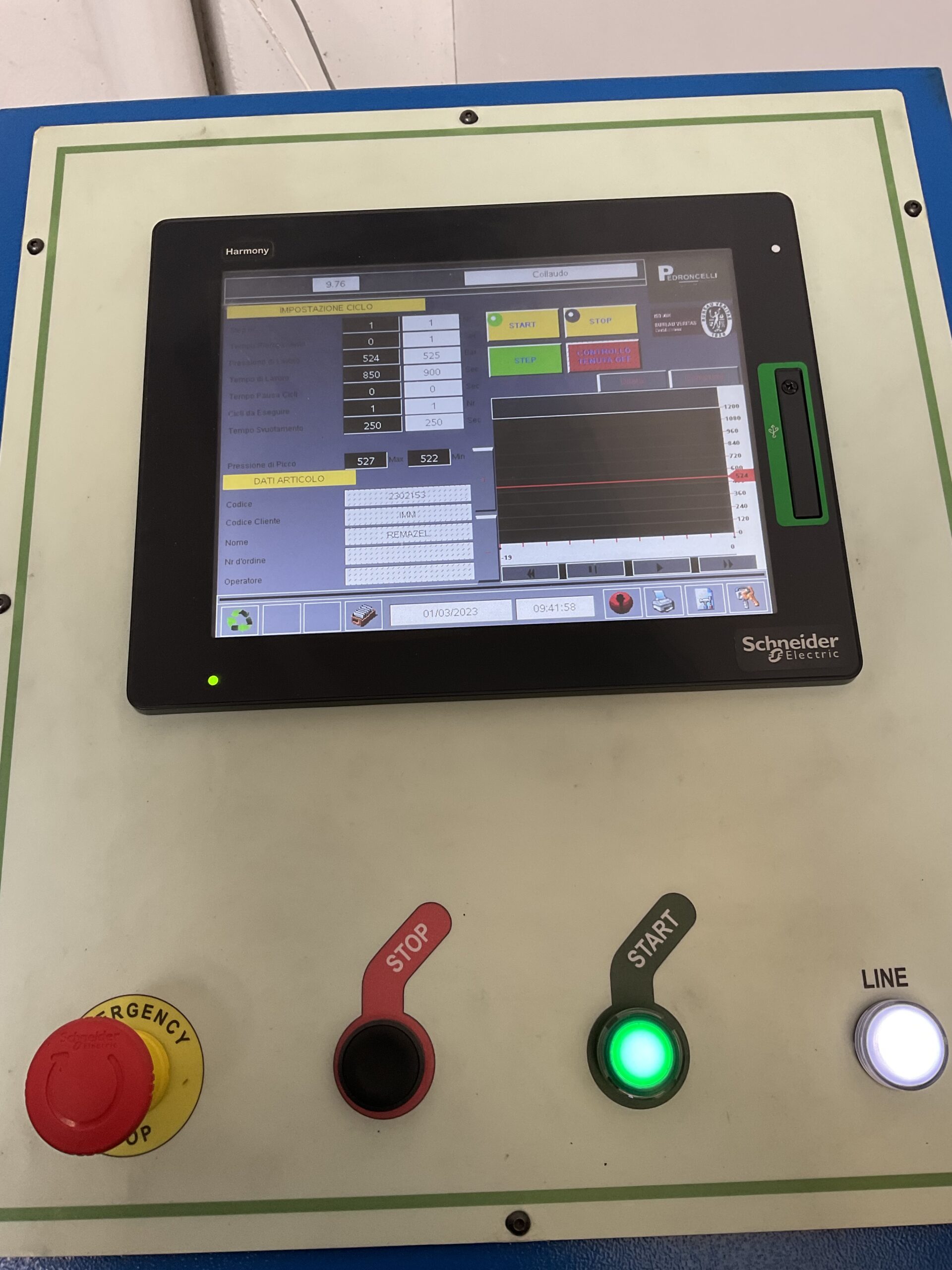

Once the tube to be tested has been connected to the appropriate coupling terminals inside the test bench, the test parameters are configured using the Cpu, the tube is then filled with the test fluid and pressurised.

The pressure test of 1.5 times working pressure (varying according to the type of hose) is continued for 15 minutes.

After the set test time has elapsed, it is possible to drain and empty the hose from the fluid and the subsequent steps of saving and archiving the test report, for each hose tested.

Hose flushing

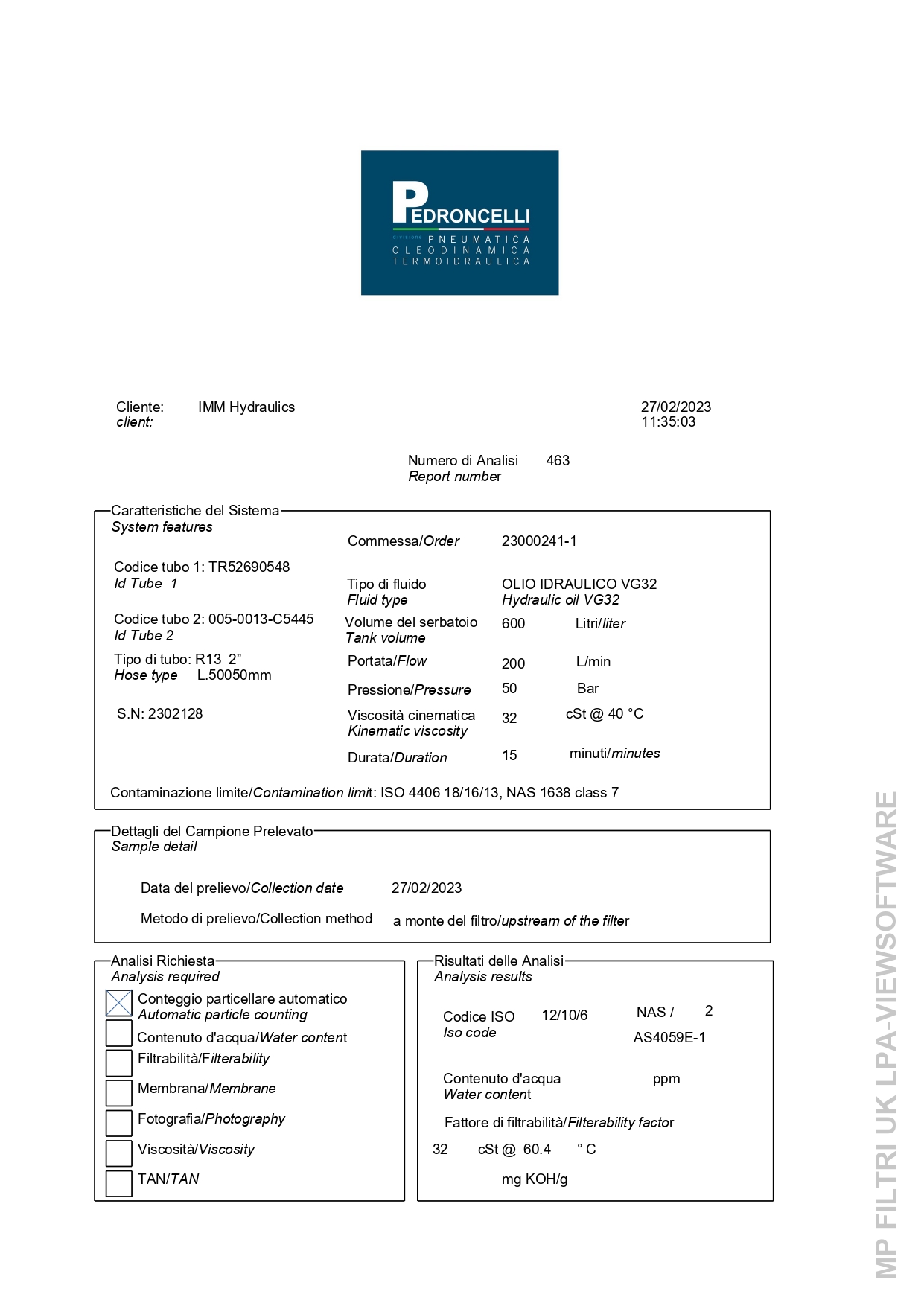

Once the previously bench-tested pipe has been connected to the connections provided on the flushing unit, the required cleaning parameters, ISO 4406 18/16/13 (NAS class 7 or higher), must be configured by correctly setting the ICM automatic particle counter installed on the unit.

With a flow rate of 200 l/min, a pressure of 50 bar and a verified oil temperature of about 60° C (as per customer request), flushing is possible.

The execution of the flushing for each hose lasts 15 minutes, as specified.

Once the pipe cleaning phase is completed, it is possible to continue saving and archiving the flushing report issued by the ICM.

By means of the compressed air fed into the pipe, the inner walls are dried of residual flushing oil and the pipe is ready to be closed by means of the appropriate dirt plugs.

Date:

17 March 2023